Properties Nylon Applications For

Nylon Washers. New Process Fibre is unique in several ways. We believe that our ability to provide OEMs with cost-effective and innovative stamping solutions for nonmetallic parts is second-to-none.

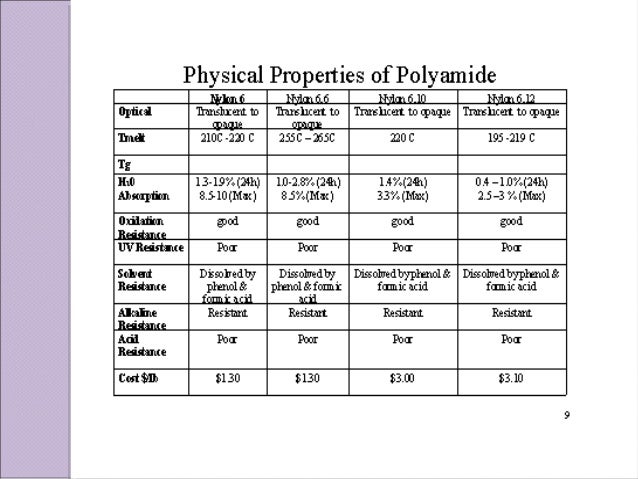

Description. Nylon-6,6 (PA66) is semicrystalline polyamide commonly used in fiber applications such as carpeting, clothing, and tire cord.

This review is provided a detailed overview of the synthesis, properties and applications of nanoparticles (NPs) exist in different forms. NPs are tiny materials having size ranges from 1 to 100 nm.

Gelatin methacryloyl (GelMA) hydrogels have been widely used for various biomedical applications due to their suitable biological properties and …

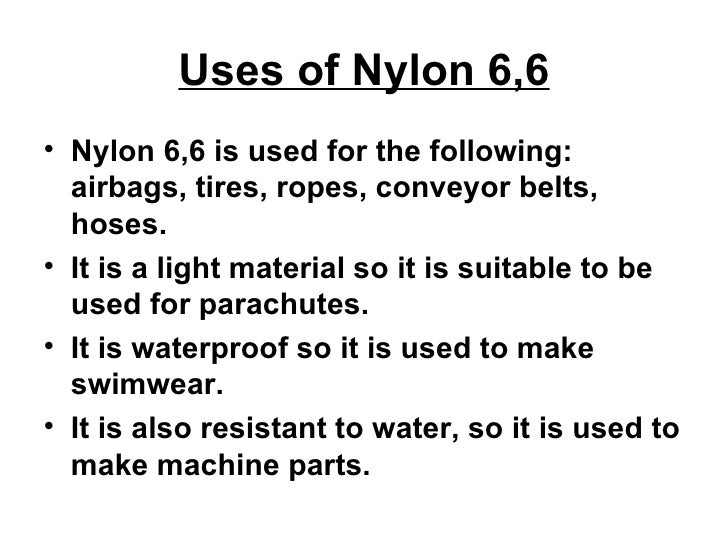

Nylon possesses many properties that make it a very useful fiber in many applications. It is very strong and elastic; its also easy to wash, and can usually be washed with similar items and does not typically require specialty laundering arrangements.

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. (Around the same time, Kohei Hoshino at Toray also succeeded in synthesizing nylon 6.)

Two molecules of water are given off and the nylon is formed. Its properties are determined by the R and R’ groups in the monomers. In nylon 6,6, R = 4C and R’ = 6C alkanes, but one also has to include the two carboxyl carbons in the diacid to get the number it donates to the chain.

ABSTRACT Here in this term paper description is given about a type of polyamide fibre i.e. Nylon-66.Here in this paper the methods of preparation of monomers, polymerisation, manufacturing methods of nylon-66, spinning process to obtain fibres, different properties and wide range of applications and uses of nylon-66 are discussed.

Nylons (Polyamides) Physical Properties. MatWeb has product data on over 12,000 different entries for nylon. This page will help you to navigate through MatWeb to find the information that you need.

Teflon and nylon are the most common polymeric engineering materials which are used to manufacture washers. They are versatile and flexible polymers. Nylon polymers are produced by reacting an amine and dicarboxylic acid while Teflon is produced through the polymerization of tetrafluoroethylene.